Study of the need to use continuous dissolved gas analysis devices in power transformer oil

Vladislav BITNEYProject Manager, Customer Service, Department of Dispatch and Technological Control and Information Technology (DTC&IT)

E-mail: [email protected]

Vitaly ULYANOVChief Expert of Digital Technologies and Platforms LLC

E-mail: [email protected]

Power transformers are one of the key elements of electric power systems [1]. Their reliable operation ensures uninterrupted power supply to industrial enterprises and household consumers. One of the main tasks facing operating services is monitoring the condition of transformers [2], especially in terms of their insulation systems, which are mainly oil. One of the effective monitoring methods is the use of continuous analysis devices for dissolved gases in transformer oil [3]. For effective management of the service life of transformers, it is important to have all kinds of data throughout their entire operational period. These data can be collected through maintenance based on the conditions and technologies of continuous online monitoring [4]. Risk can be characterized as the "effect of uncertainty", so the main goal of risk management is to assess the probability of defects and ensure reliable operating conditions for the equipment throughout its service life [5]. The scope of repair work is planned taking into account the quality and completeness of available information on the condition of the substation equipment [6, 7]. Modern substation asset maintenance strategies are aimed at moving towards condition-based maintenance [8, 9]. Although predictive tools are not able to accurately estimate the remaining service life of equipment, they can be used to analyze further asset degradation.

Power transformers can be subject to various types of damage, the consequences of which can be very serious, including emergency shutdowns and corresponding economic losses [10]. One of the most important aspects of the transformer’s condition is its insulating oil, which can accumulate dissolved gases formed as a result of thermal and electrical processes occurring inside the device [11]. These gases are indicators of various conditions and faults, such as overheating, electrical discharges or insulation degradation.

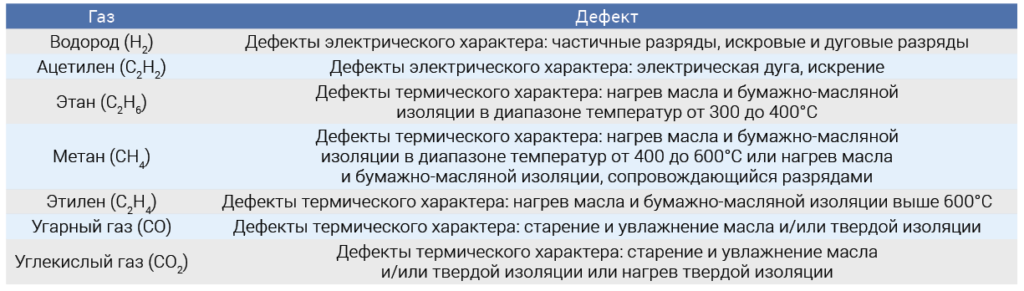

Dissolved gas chromatography (DGC) is a method used to assess the condition of a transformer through the analysis of transformer oil [12]. This method serves as a tool for early diagnostics of emerging equipment defects. With the help of modern technical means, it is possible to carry out monitoring without the need for specialized laboratory equipment. The devices provide continuous sampling, which allows tracking the dynamics of faults and taking the necessary actions in a timely manner. Gases, mainly hydrocarbon compounds such as hydrogen, methane, ethane, ethylene and acetylene, as well as carbon monoxide and dioxide, appear in transformer oil during its operation and serve as indicators of possible faults. These gases are formed as a result of damage to the transformer tank, which can be caused by sparking, corona discharges, overheating of oil or paper insulation. A change in the concentration of these gases signals the possible occurrence of a serious or destructive internal defect, which helps prevent emergency equipment failure [13]. DGC can be used with various types of insulating oils used to fill transformers. Each type of oil has its own characteristics in terms of resistance to aging and thermal characteristics, which in turn affects the methods of diagnosing faults in transformer oil, depending on the selected oil. Typical gases formed from mineral oil and cellulose (paper and cardboard) in transformers include: hydrogen (H2); methane (CH4); ethane (C2H6); ethylene (C2H4); acetylene (C2H2); carbon monoxide (CO); carbon dioxide (CO2). Additionally, oxygen and nitrogen are always present, and their concentration varies depending on the tightness of the transformer housing. Defects detected by CADG are divided into two groups: - thermal defects; - insulation discharges.

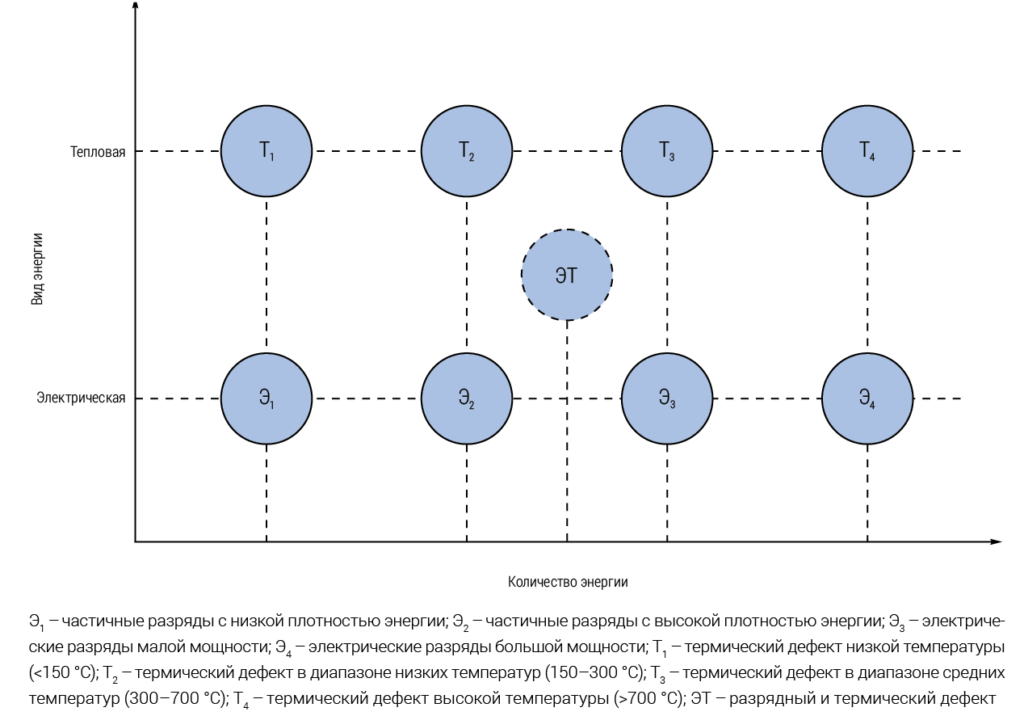

The release of destruction products, including gases, occurs as a result of abnormal local release of energy and temperature increase in defects of the first group. In those defects that are associated with electrical discharges, gases are formed mainly as a result of ionization processes. Thus, in addition to the thermal and electrical nature of the defects detected by CARG, their type also depends on the volume of energy released during the corresponding process (Fig. 1).

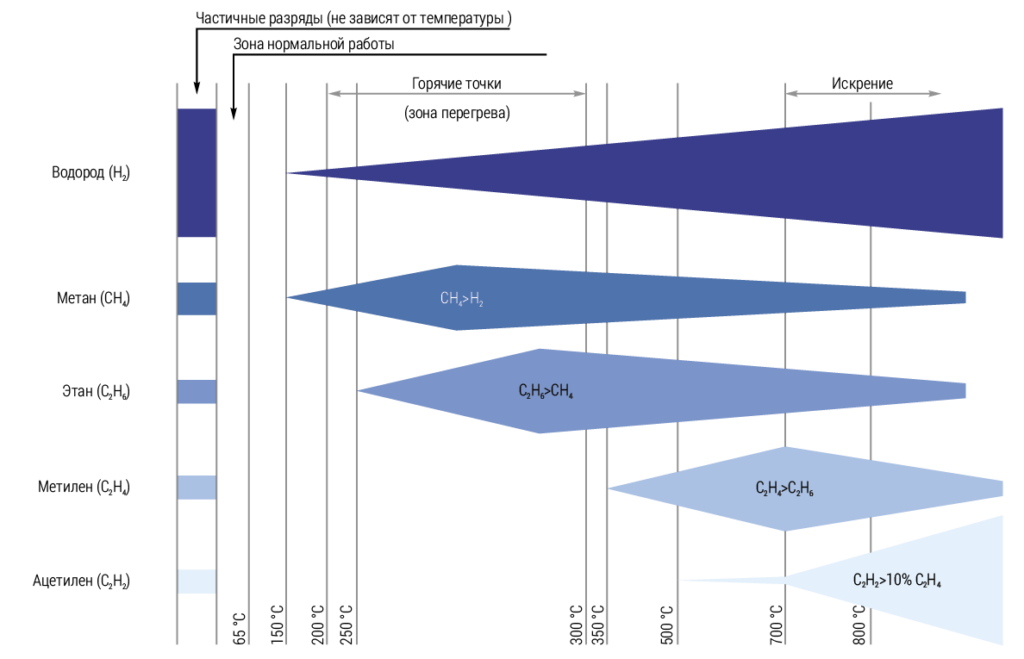

Accurate online monitoring of dissolved gases allows for almost immediate detection or diagnosis of any initial faults occurring in the liquid or solid insulation of a transformer, which helps to avoid serious breakdowns. The use of limit values for gas concentrations and fault diagnostic methods defined in standards helps to detect and identify early stages of defect development [14]. The most informative gases for detecting initial faults are hydrogen, moisture and carbon monoxide. Hydrogen is formed in greater or lesser quantities during any electrical and thermal faults occurring in oil. Fig. 2 conventionally shows the dependence of the intensity of flammable gas emission on temperature [15]. The left part of the diagram shows the approximate proportions of gases occurring under partial discharge conditions; as can be seen, the amount of hydrogen significantly exceeds the values of other gases. From the gas evolution graph, it can be seen that hydrogen is released at temperatures from 150 °C, while other gases such as ethylene or acetylene require specific conditions and high temperatures in the range of 350 to 500 °C. In addition, gases such as methane and ethane are not formed at very high temperatures. Table 1 shows the relationship between the main gases and the most typical types of defects.

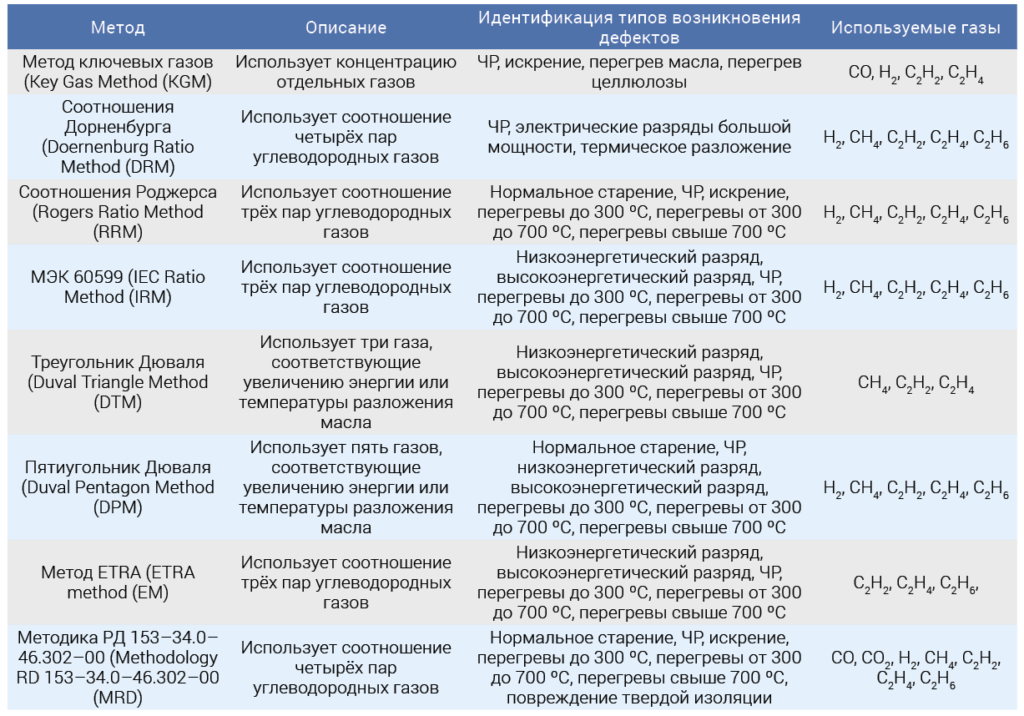

The type of fault can be determined by the ratio of gases in certain proportions. The introduction of gas chromatographic analysis has significantly improved the monitoring of the condition of windings, which, for example, made it possible to "move moistening of solid insulation to the category of comparatively rare causes of damage to oil-filled transformers, although two decades ago it occupied the first place" [17]. The most common methods used in world practice were considered: the key gas method [18], Dornenburg relations [19], Rogers relations [20], IEC 60599 [21], Duval triangle [22, 23], Duval pentagon [24], ETRA [25], as well as the RD 153-34.0-46.302-00 [26] method approved in the Russian Federation. All these methods are based on gas concentration parameters, but differ in assessment criteria, analysis methods and required initial data. Table 2 presents the main characteristics of the above methods [27, 28].

Some studies show that the best method for detecting transformer insulation faults is the Duval Triangle Method (DTM). The Duval Pentagon Method (DPM) was created to refine the results of the DTM, as the DPM takes into account the normal aging of the transformer insulation. Although the DPM is shown to be the best method for detecting faults, it should be noted that it is a fairly new method that needs further study to improve its reliability. Therefore, the DTM is the method recognized as the best for diagnosing transformer insulation faults.

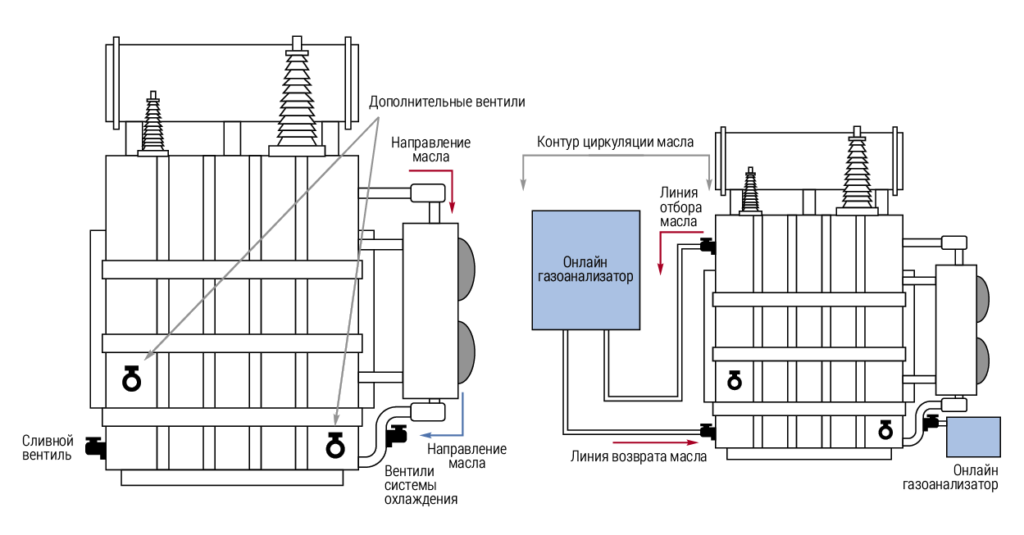

Online monitoring devices measure the concentrations of dissolved gases in transformer oil and detect or identify internal faults. The installation methods for online monitoring devices depend on the type of sensor and the transformer design. Typically, installation is carried out using one or two valves on the transformer. Figure 3 shows the possible positions of the valves on a power transformer. Installation of a monitoring device with one valve is carried out by attaching it directly to the valve on the transformer flange. In this case, the optimal location for installation is the flange on the outlet pipe of the cooling circuit, where there is a constant flow of oil, which makes the sample more representative. If this option is not available, an alternative is a process hatch of the transformer tank with a pre-prepared flange, located high enough from the bottom. A drain valve is not recommended for installation, since it is located at the bottom of the transformer, where there is no oil flow, which increases the risk of contaminated sediment formation.

When installing monitors with two valves, a closed circuit is created through which oil passes through the device (see Fig. 3). One valve serves to supply oil, and the other to return it. As in the case of one valve, the device must take oil from a place where there is a flow: this can be a radiator outlet pipe, the upper flange of a thermosiphon filter, or a process hatch located far enough from the bottom of the tank. The check valve can be a drain or auxiliary valve if it is located below the supply valve.

Installation methods differ not only in the number of valves used. When a membrane sensor is installed on a valve, the oil sample is collected and returned to the same space, which complicates sample circulation and increases the sensor's response time to changes in the oil composition in the tank. Some devices create oil circulation in the valve area using heating elements and oil convection at the sampling point. The best solution is to insert the device's sensitive sensor through a ball valve directly into the internal oil flow in the tank. The advantages of such devices are their compactness, ease of installation, and the absence of the need for an internal pump.

Modern devices do not require sending samples to the laboratory. Chromatographs provide the ability to continuously monitor online, taking samples at set intervals. Most modern devices have the following functions and characteristics [3]: measurement of the content of the main gases (including hydrogen, oxygen, carbon dioxide, methane, nitrogen and others); error of no more than 5%; measurement of moisture content in oil; determination of the temperature of the environment; sampling with a frequency of 2 to 24 hours, automatic transition to more frequent analysis when excess concentration occurs; automatic calibration function; expert software; minimal maintenance requirements. Structurally, the equipment for chromatographic analysis of dissolved gases consists of a system of tubes, a sampling device and an electronic analytical unit. The sampling device and the analytical unit are combined into one housing.

Serveron TM2/TM3/TM8 [29]. The Serveron online flow-type chromatograph is a real-time transformer monitoring system designed for continuous analysis of dissolved gases in oil (Fig. 4).

Key features of Serveron TM2/TM3/TM8: continuous sampling at user-defined intervals (from 2 to 12 hours) and automatic transition to more frequent sampling when gas concentrations increase; analysis of dissolved gases according to RD 153–34.0–46.302–00 with an error of no more than 5%; expert software TM View using the main diagnostic tools: Duval triangle/pentagon and Rogers coefficients; automatic calibration; minimal regular maintenance; highly accurate analysis of dissolved gases and moisture in both mineral oils and various essential oils.

The technical characteristics of the Serveron online flow chromatograph are presented in Table 3.

TOTUS ST G9 [30]. The power transformer monitoring system includes the TOTUS ST G9 transformer oil dissolved gas analyzer (see Fig. 5) and the INTEGO bushing insulation and partial discharge parameters monitoring system developed by CAMLIN Limited. These devices are designed to monitor and analyze key diagnostic characteristics such as the composition of gases dissolved in oil, the capacity and loss tangent of bushings, the level of partial discharges, loads and temperatures, as well as the results of calculation models, which allows obtaining up-to-date and accurate information on the current state of the transformer.

Key features of TOTUS ST G9: Monitoring of nine main gases: photoacoustic spectroscopy for six gases (CH4, C2H4, C2H6, C2H2, CO, CO2), the remaining gases (H2, O2) are detected by sensors, and the level (N2) is calculated; no need for consumables and calibration gas mixtures; built-in web server and web-based software - full control and communication via secure web access, including applications for smartphones and tablets; additional software for diagnostics and offline data analysis; full compatibility with facility management systems (e.g. SCADA); extensive communication and I/O capabilities for modern equipment owners - collecting data from third-party monitoring devices; standard function for monitoring the load and main temperatures of high-voltage equipment.

Technical characteristics of the online chromatograph TOTUS ST G9 are presented in Table 4.

GE Energy TAPTRANS [31]. A device (Fig. 6) that allows the display on a single monitor of the CADG data in the main oil tank and in the on-load regulation device (OLTC), including the tap-off device and switch tanks, operating in a single unit. Key features of GE Energy TAPTRANS: use of only one device for monitoring in the main oil tank and in the on-load regulation device (OLTC), including the tap-off device and switch tanks; CADG for eight gases + moisture content; no need for carrier gases or calibration gases; hourly measurements; load monitoring capability; no use of membranes or vacuum sampling;

secure storage of up to 10,000 records.

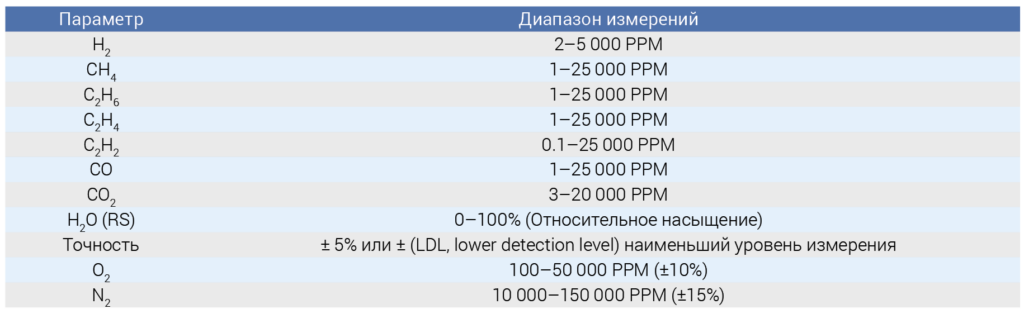

The technical characteristics of the GE Energy TAPTRANS online chromatograph are presented in Table 5.

The clear advantages of using continuous analysis devices are:Early detection of faults. The devices allow monitoring changes in the concentration of dissolved gases in real time, which makes it possible to promptly respond to various anomalies. For example, an increase in the concentration of hydrogen can indicate overheating, while high levels of acetylene are often associated with electrical discharges inside the transformer. The devices also allow identifying the relationship between gas anomalies and external parameters and events, such as transformer load, oil temperature, change in the state of the tap changer under load, etc.Increased reliability. Regular monitoring of the transformer condition helps to ensure its more stable and safe operation. This significantly reduces the risk of emergency situations and, as a result, improves the reliability of the power supply.Optimization of maintenance. The continuous analysis system allows for more accurate maintenance planning. The data obtained can be used to determine when and what actions need to be taken to prevent potential problems, which significantly reduces maintenance and repair costs.Trend analysis and forecasting. Continuous analysis allows you to accumulate data on the state of the transformer, which in turn helps in predicting its condition based on historical data. This may become the basis for making more reasonable decisions on the modernization or replacement of equipment. Despite the obvious advantages, the use of continuous analysis of dissolved gases in the oil of transformers is not completely indisputable. The main disadvantages include: high costs for installation and maintenance. The introduction of modern monitoring systems may require significant investments both for the initial installation and regular maintenance and calibration of devices. The performance of personnel training. Effective use and interpretation of data requires qualified personnel, which also implies additional training costs. Graduates of accuracy. Some factors, such as temperature or pressure, can affect the accuracy of measurements, which requires special attention in the interpretation of the results.

Reduced information content of software. The need to develop new software was revealed, because in the considered devices of online monitoring of dissolved gases in oil, only part of the methods of interpreting the results of chromatographic analyzes of dissolved gas in oil are used.

The analysis of dissolved gases in transformer oil is one of the most popular methods for assessing the technical condition of power transformers. In real time monitoring makes it possible to control the serviceability of the transformers by early detection of potential malfunctions in liquid or solid isolation. As part of this study, an overview of equipment for online monitoring DGA of power transformers was carried out. It is important to consider constructive solutions regarding the selection and analysis of the gas mixture, as well as the methods used to diagnose malfunctions when choosing an online monitoring system. The choice of devices is greatly limited depending on the required number of gases to identify faults, taking into account the structure and analytical capabilities. At the same time, one should take into account the need for regular maintenance of most monitoring sensors or to consider the possibility of using fully maintenance devices. The study of the need to use continuously analysis of dissolved gases in oil transformers shows that the advantages of such systems are significant and can very effectively contribute to increasing the reliability of the transformers. Despite the difficulties, most experts agree that these technologies become an integral part of modern electricity management systems. Investments in such systems can ultimately lead to a significant reduction in emergency situations and an increase in the life of transformer equipment. The use of continuous analysis devices is a step towards the safer and more reliable operation of energy systems. In the framework of the continuation of the study, it is planned to create software. The developed software for assessing the technical condition of power transformers will ensure a more reliable result due to: - taking into account the totality of all the main methods of interpreting the results of chromatographic analyzes of dissolved gases in oil; - taking into account the structural features of power transformers and the duration of their operation; - the use of the absolute values of the growth rate of gases instead of relative values as a criterion the speed of development of the defect in TR;

- the formation of recommendations for the implementation of the necessary measures to eliminate the identified defects.

energypolicy