GE Vernova, IHI Launch Test Hub to Enable 100% Ammonia Combustion in F-Class Gas Turbines by 2030

Japanese integrated heavy industry group IHI Corp. and GE Vernova have inaugurated a new Large-Scale Combustion Test (LCT) facility at IHI’s Aioi Works in Hyogo, Japan, marking a pivotal step in their joint effort to commercialize gas turbine combustors capable of burning up to 100% ammonia by 2030. The facility will accelerate full-scale prototype testing starting in summer 2025, the partners said.

The new Large-scale Combustion Test facility (LCT) stems from a Joint Development Agreement (JDA) signed in January 2024. Under the agreement, the companies set out to develop a retrofittable 100% ammonia-capable gas turbine combustion system compatible with GE’s 6F.03, 7F, and 9F models, targeting a potential commercially available product by 2030.

As POWER has reported, the companies signed a memorandum of understanding in June 2021 to define an “ammonia gas turbine business roadmap,” including joint research on market potential, feasibility studies for ammonia as a gas plant fuel in Japan and Asia, and initial technology scoping. In February 2023, after a year-long study, the companies concluded that ammonia could be a potentially lower-cost alternative fuel for gas turbines in Japan than liquid hydrogen if the full import value stream is considered.

The January 2024 JDA built on IHI’s work to develop a combustor for a 2-MW class IM270 gas turbine with funding from Japan’s New Energy and Industrial Technology Development Organization (NEDO). In June 2022, IHI conducted tests to mono-fire liquid ammonia in the turbine at its Yokohama Works facility using a novel combustion method that involved liquid ammonia being directly sprayed in the gas turbine combustor. The tests showed a greenhouse gas reduction rate—including both CO₂ and nitrous oxide (N₂O)—exceeding 99%, even when the ammonia fuel ratio was between 70% and 100%.

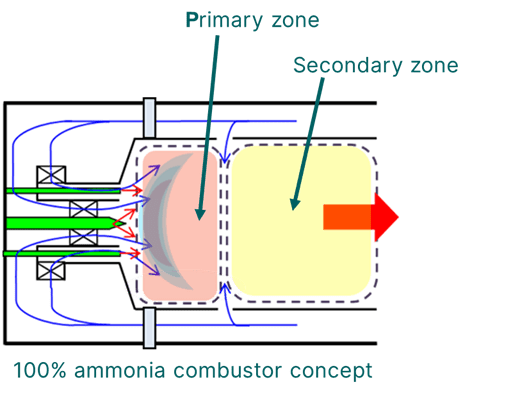

LCT to Test Ammonia Combustion Under Real-World Operating ConditionsTraditional dry-low NOx (DLN) combustors, which are typically optimized for methane, are fundamentally lean-premixed systems that minimize nitrogen oxide (NOx) by reducing flame temperature. A key challenge, however, has been to address ammonia’s high nitrogen content (about 83% by mass), which leads to excessive NOx formation under lean conditions. IHI’s technology adopts a two-stage combustion system that features a fuel-rich “rich” stage followed by a lean stage. In the first stage, limited oxygen availability suppresses NOx formation as ammonia decomposes. The second stage ensures complete combustion with additional air, further reducing residual ammonia and unburned fuel.

The new LCT, which the companies launched on Monday, will begin rigorous combustion tests of the technology this summer using full-scale prototype combustors running on 100% ammonia. A key goal is to validate performance, reliability, and emissions compliance under real-world conditions. “The new test facility is engineered to test advanced combustion systems at GE Vernova’s F-class gas turbine operating conditions, including pressure, temperature, and both air and fuel flow rates,” the companies noted in a statement.

“This milestone marks a significant step forward in the joint technology roadmap sealed with a Joint Development Agreement in 2024, aiming to lead to a 100% ammonia capable combustion system by 2030,” explained Kensuke Yamamoto, IHI executive officer officer, VP of Business Development Division, and GM of Ammonia Value Chain Project Department. “IHI has developed a 100% ammonia firing gas turbine IM270 (output 2 MW) and will level the technology to develop large-scale combustion technology. IHI’s combustor development role lies in this new flagship test facility, which will be a crucial hub for IHI’s and GE Vernova’s project. The establishment of the LCT underscores IHI’s and GE Vernova’s commitment to driving innovation in more sustainable energy solutions, with ammonia as a promising fuel for future power generation.”

The companies noted the collaboration between the two companies includes synergies “across IHI ammonia combustion expertise and GE Vernova global technical teams, and shared best practices developed at GE Vernova’s advanced combustion test facility in Greenville, South Carolina.”

Ammonia, which has long been utilized in industrial applications such as fertilizer and chemical raw material, has been touted as a carrier for hydrogen, given that it could enable efficient, lower-cost transport and storage. Experts note that while clean ammonia holds promise as a low-carbon fuel for power and shipping, its widespread adoption faces significant hurdles, including that the cost of green ammonia remains prohibitively high—up to six times more than conventional brown ammonia—owing to expensive electrolysis and limited renewable power. Blue ammonia offers a more viable near-term alternative, but still requires costly carbon capture retrofits. Ammonia’s toxicity, potential NOx emissions, and public safety concerns also pose barriers.

Meanwhile, despite ammonia’s promise as a zero-carbon fuel for power generation, market momentum has been slow owing to a combination of technical, economic, and practical barriers. A key hurdle has been to customize turbines to meet stringent single-digit NOx regulations in major markets like the U.S. and Japan. So far, no original equipment manufacturer (OEM) has yet commercialized a gas turbine capable of operating on 100% ammonia fuel, though progress is continuing for engineering validation and demonstration.

Sembcorp Industries in Singapore is notably working with IHI and GE Vernova to explore retrofitting two GE Vernova 9F turbines at the 815-MW Sakra cogeneration plant for 100% ammonia operation in a project that could become one of the world’s first commercial-scale demonstrations of ammonia-fired combined cycle generation. Mitsubishi Power is meanwhile developing a 40-MW class turbine based on its H-25 model, capable of direct ammonia combustion. MAN Energy Solutions—now rebranded as Everllence—is also advancing ammonia-fueled engine technology for industrial and utility-scale power, building on existing compressor solutions for ammonia processes with the development of two-stroke engines (12–68 MW) and four-stroke dual-fuel engines (26 MW).

GE Vernova, whose installed global fleet includes an estimated 7,000 gas turbines, is notably executing a multi-phase decarbonization strategy for its gas turbine fleet, targeting near-term carbon intensity reductions and long-term net-zero emissions. According to the company’s June 2025–released sustainability report, the company has set a near-term goal to reduce Scope 1 and 2 emissions intensity by 50% by 2030 (from a 2019 baseline), and has committed to achieving net-zero Scope 3 emissions—those from the use of sold products, including gas turbines—by 2050. To advance its goal, GE Vernova is integrating hydrogen capabilities into its new and existing gas turbines, enabling up to 100% hydrogen combustion in select models, and is piloting post-combustion carbon capture retrofits on operating fleets. The company is also deploying advanced digital solutions, including artificial intelligence–driven performance optimizations, to reduce fuel consumption and emissions across gas turbine operations.

So far, GE Vernova reports that more than 120 of its gas turbines across seven models—including the 7HA, 9HA, 7F, 6F, 6B, 9E, and LM6000—have already operated on hydrogen or hydrogen-natural gas blends, which amass more than 8.5 million operating hours. While its LM6000 aeroderivative turbine has demonstrated successful field operation on up to 100% hydrogen, its 7HA.03 heavy-duty turbine is being developed to support combustion of hydrogen blends up to 50% by volume. Those capabilities bolstered by GE Vernova’s continued advancement of DLN combustion systems, but the company suggests it is also actively working with global customers to validate hydrogen performance and scale deployment across both new-build and retrofit projects, while also supporting government-backed R&D efforts, like the U.S. Department of Energy’s HyBlend program, to accelerate commercial readiness and integration of hydrogen into dispatchable generation.

“There are many benefits to using ammonia as a power generation fuel, including having an existing global supply chain,” the company notes. “As a fuel, ammonia is composed of nitrogen and hydrogen; no carbon. Therefore, a gas turbine operating on ammonia will have essentially zero carbon emissions (there may be trace emissions due to the carbon dioxide present in the air used for combustion).” In addition, “The implementation challenges associated with hydrogen include limited pipeline infrastructure and transportation vessels, as well as extreme cooling temperatures. There are very few pipelines capable of transporting hydrogen. Condensing hydrogen from a gas to a liquid requires cooling to -253 °C (-423 °F). Ammonia has to be cooled only to -33 °C (-28 °F) to be stored as a liquid; a much warmer temperature than hydrogen. Liquid hydrogen can be transported by ship, but there is limited capability today,” it says.

Ammonia’s abundance is also a major plus, it suggests. “Ammonia is the second most produced chemical worldwide; of the amount produced, approximately 10% is transported by ship each year. Around 170 vessels are in operation that can carry ammonia, of which 40 carry ammonia on a continual basis, which implies sufficient port and transport infrastructure. Since ammonia is produced from hydrogen, it can be converted or cracked back to hydrogen for end use after transport. Therefore, there is growing interest in using ammonia as a method to ship hydrogen.”

GE Vernova noted market interest is growing in countries like China, Indonesia, Malaysia, Thailand, and Japan, which “have expressed their intent in exploring ammonia co-firing at coal plants as a part of their decarbonization efforts. There is increased government support in the region, evident in recent developments in Japan and South Korea.” Interest in ammonia as a potential gas power fuel is also tangible, it suggests.

Start of operations at the new LCT marks a new phase in its testing required for power plant systems, the company said. “This announcement signals a shift from initial studies on the ammonia value chain to the practical implementation of technologies and engineering projects, aiming to decarbonize power generation by using ammonia as a fuel,” said Jeffrey Goldmeer, GE Vernova senior director for Technology Strategy.“This marks a new phase of collaboration between GE Vernova and IHI, with the goal of developing decarbonization pathways that safeguard existing power generation investments.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).

powermag