Engineered for Challenging Soils, GEOWEB® Geocells Create a Reliable Access Road Over Soft Subgrade

Bypass Road AB, Canada

A project owner was faced with rehabilitating and upgrading an existing energy access road to handle the rigors of a new plant expansion and commissioning. The energy plant, located south of Conklin, required improvements to the 11.5 km (7.1 mile) bypass road, which originally served as a secondary access route to regional facilities including Cenovus Christina Lake, Devon Pike, Jackfish, and Kirby.

The access road had not been in use for several years and became nearly impassable during spring and summer rain events due to neglect and lack of maintenance. To drastically improve the performance of the road, the project owners turned to Presto Geosystems’ Canadian distributor, Layfield Group, a well-known geosynthetics supplier and installer in the region.

Keeping the road operational during initial subgrade preparation and the staging of reinforcement materials and gravel in advance of the road being closed for repairs was a concern. Work also needed to be completed within a short construction timeline. Layfield’s execution plan called for the road to be closed for less than two weeks.

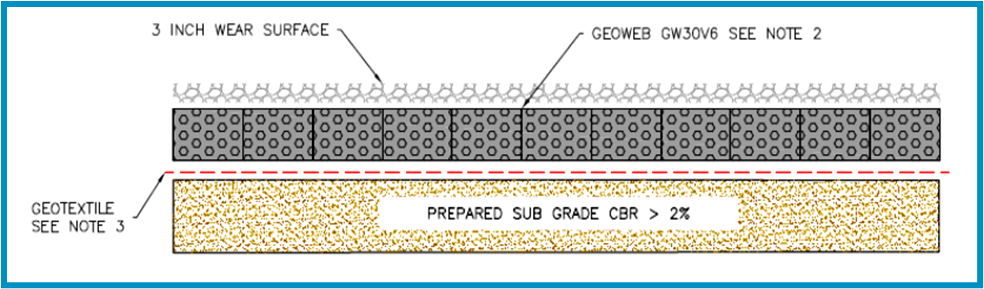

The project team decided to use the GEOWEB® Load Support System along with Mirafi’s enhanced woven geotextile. These materials were selected due to their performance and speed of deployment, which was crucial given the tight construction timeline. The GEOWEB GW30V6 mid-sized cell panels and Mirafi HP270 were specified and supplied for the project.

Several sections of the access road were in such poor condition (with a CBR of 1.5%) that a second layer of GEOWEB geocells and the geotextile for additional sub-base reinforcement was considered. However, due to the success of the initial deployment, a second layer was no longer needed.

Layfield’s experienced team provided on-site technical support and installation training for the general contractor. They worked closely with the contractor and the project’s on-site manager to ensure a smooth and timely deployment of the materials.

Staging the vast amount of materials for the project required serious planning. Coordinating the logistics to stage 335 pallets of GEOWEB panels and over 12 km (7.5 miles) of factory-sewn HP270 enhanced geotextile was a significant undertaking. Thanks to the logistical finesse of Layfield’s shipping department, the task was completed with ease.

Project Completion & ResultsThe projected was successfully completed and according to plan, despite an unusually wet construction season. The initial deployment of the GEOWEB system and Mirafi enhanced woven geotextile in the areas identified as very poor were so successful that a second layer was not required.

A crucial factor in the installation speed was the use of the patented ATRA® Key device to connect GEOWEB panels side-to-side and end-to-end. The corrosion-resistant keys are the strongest and safest connection method, dramatically speeding deployment of the GEOWEB panels. The road has been in service since early 2019 and holding up exceptionally well.

To combat soft subgrade challenges, roads built with the GEOWEB 3D geocells, enhanced woven geotextile reinforcement, and aggregate infill are extremely stable and capable of supporting heavy traffic.

- Low-maintenance, 3D-confined aggregate surface is highly resistant to rutting and requires virtually no maintenance.

- Lower-cost, local fill, coarse sand or recycled materials may be used for panel infill.

- GEOWEB panels and geotextile rolls are easy to deploy and install, even in remote or difficult-access locations.

- The surface is ready for traffic immediately after infilling and compaction.

For project assistance in the US, contact Presto Geosystems at 800-548-3424. For project assistance in Canada, contact Presto Geosystems’ Canadian distributor Layfield Group at 888-748-7905.

Share This:

More News Articlesenergynow